"The manufacturer of lumber is not a manufacture only. Stores, dwellings, offices and other necessary facilities must be provided. The sawmill owner is a railroad builder and operator, a storekeeper and the ruler of an estate equal in area and complexity of difficulties encountered in many countries."

- American Lumberman 1908

Historic Long Leaf, Louisiana

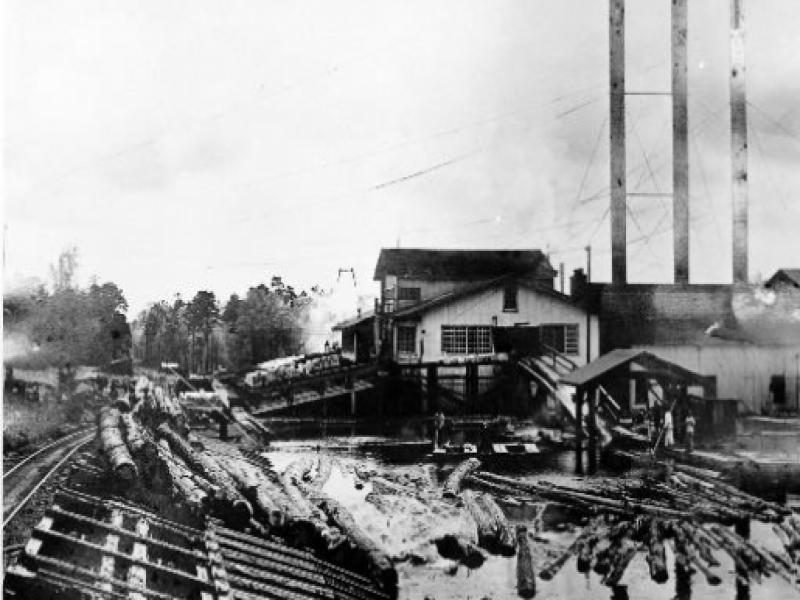

Long Leaf was a town built by the Crowell & Spencer Lumber Company to provide employees for the sawmill being built in 1893. Of immediate concern was housing for their employees, but also needed was the support facilities provided by a town. These support facilities included a commissary, hotel, doctor’s office, post office, churches, and schools. The sawmill was constructed near the timber to be harvested and milled, so all the town had to be provid for about 300 workers and their families, or about 2,500 individuals. As typical with many sawmills, a fire destroyed the first mill and it had to be rebuilt. Although few of the original residences remain, the sawmill complex itself is one of the most complete in the country.

Sawmill

Most of the sawmill buildings were built in the early 1900s. Steam powered logging and milling equipment provided logs and milled them into lumber for markets until the mid-1950s when a conversion to electricity occurred. The trees were cut with cross-cut saws and axes. The logs were pulled to the railroad track where they were loaded on train cars for transport to the mill. Dumped into the mill pond, they were then pulled into the mill an sawn into lumber. Processed lumber was then sorted and graded for further processing. The sawmill building was a huge complex of noise and activity. The mill had the capacity to cut about 100,000 board feet of lumber per day, but usually only about 60,000 board feet were produced daily.

Dry Kiln

Lumber leaving the sawmill is called green because it is full of moisture and it must be dried to a lower moisture content before it can be processed into finished lumber. The lumber could be dried in two different ways. It could be stacked with stickers between each layer to allow the air to flow freely. The other method, kiln drying, uses steam application in buildings called kilns. Lumber in outside stacks took weeks to dry, while drying in the kiln took only 24 hours. If markets were good for lumber, drying in the kiln was preferred.

Planer Mill

Finished lumber and various moldings were produced in this building which was built about 1910. Here the lumber was planed to remove the rough edges the sawmill from sawmill cutting. When lumber left the planer mill, it had the smooth surfaces we are familiar with when we by lumber today. They also had various milling machines that produced the decorative trim used in homes.

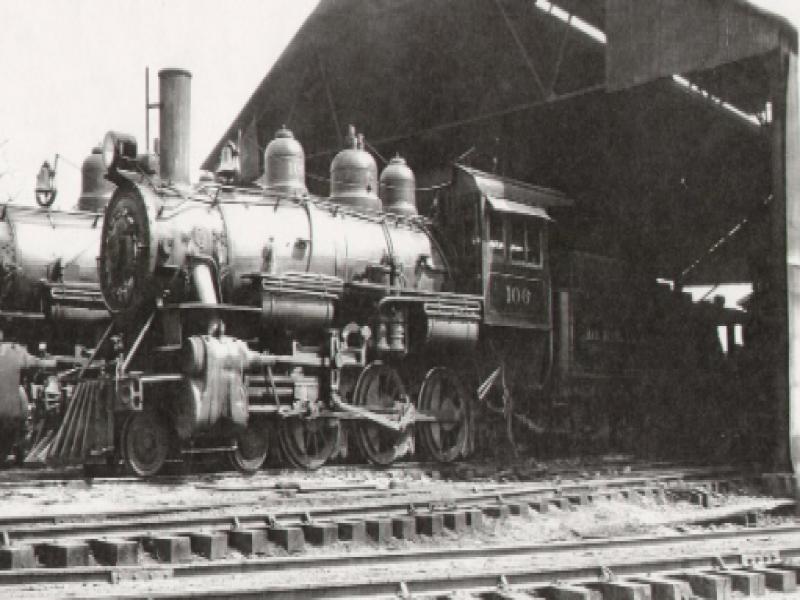

Roundhouse

This is where the steam locomotives for the railroad were serviced. The building was always called a roundhouse by the mill personnel even though it was not round nor had a turntable for turning the engines. A service pit located under one of the tracks was use by workers to service and repair the engines.

Machine Shop

If a piece of equipment broke, the machine shop was where it could be repaired. There were no stores to go to, so if anything was needed the machine shop was where replacement parts were made. Laths and all sorts of machinery was available to repair equipment. Long Leaf has one of the best preserved and equipped belt-driven machine shops in the South. Several of the machines have been brought back into working condition to produce needed parts for the museum.

Post Office

An essential component of any town is its post office. At Long Leaf, there are two post office buildings. The original office was established in 1895 and burned. Another post office was built in 1920 and was originally located across the tracks from where it sits today. It was built in 1920. A newer one is still actively used by the Postal Service. Records we have for the building show an inventory of all fixtures. Total cost of all fixtures $385.50.

Commissary

The Commissary provides for an entrance to the Museum, payment of admission, an orientation video, gift shop, and exhibits about the history of the mill town of Long Leaf. It also houses the Terrell World War II exhibit. Historically the Commissary served numerous functions for the mill town. It was the company store where a variety of dry goods and groceries were available for purchase. It also housed a café where hot lunches and cold drinks were served. In keeping with the standard practice of the times, this area in the Commissary was segregated with a lattice screen separating black from white customers.

Town Housing

Worker housing at Long Leaf was typical for early 20th century sawmills. Housing was segregated and white employees had larger homes than African American and Mexican families. Workers paid a monthly rent and a small amount was deducted to cover the cost of medical care—a doctor lived on site. Houses were small, usually two or three rooms and electricity for lighting was provided.